With the Summer Solstice now behind us, it's time to celebrate this much-anticipated season by enjoying the outdoors. I enjoy taking my daily neighborhood walks early in the day. It's during these walks that I stop to admire the tiled walks and entries. In this post, I'll be sharing some of my favorites that not only add to a home's uniqueness, but those that also provide welcoming curb appeal.

|

| Rustic Pavers in Mission Red create a charming tiled walk for this home |

It's easy to see why a tiled cement sidewalk offers so much more style than a typical grey, poured sidewalk. Colorful tiled walks provide a bright, eye-catching entry to a home. Red is a great choice for Mediterranean, Spanish, Spanish Colonial, Spanish Revival, and Adobe style homes. If you have a large landing or patio, then consider adding a medallion or patterned stair riser tiles.

Further, the exquisite beauty of hand-poured cement tile in plain colors is unmatched. You can see the hand of the tile artisan in the installation with the variation in color and shade from tile to tile. The floor or sidewalk almost shimmers like a gem, especially in full light. Look at the Heritage Indian Red walk below and you'll see what I mean. The tiled stair risers catch your attention, while the plain red walk causes you to linger and pause.

|

| Plain cement tile, Heritage Indian Red, makes for a bright and eye-catching entrance. A medallion using Traditional Alcala corner pieces adds interest and brings attention to the stair riser pattern |

|

| Square concrete tiles, Rustic Pavers in Cotto Dark, are laid in a running bond pattern to create a fresh look |

Use our Rustic Pavers, laid on a wide grout line to accommodate their irregular shape, to create Old World elegance. If you want to replicated an antique look use Cotto Dark; Cotto Gold looks like traditional Spanish bisque. Or use a blend of the two, Spanish Cotto, to create lots of charm and interest with the color variation. Additionally, our Rustic Pavers color palette includes the tones found in Mexican pavers or Saltillo tile. So, you can even replicate the look of Saltillo, too.

|

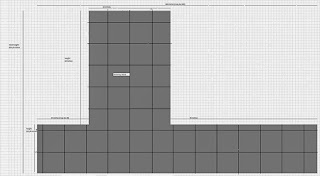

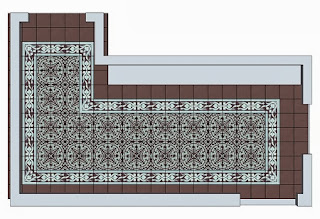

| This long entry path is made interesting by using Arabesque Octagon Rustic pavers in Cotto Dark. |

DESIGN TIP: When using shapes that are not rectangular or square, like hexagons and octagons, make sure to frame the edge of each side of the path with a rectangular tile.

|

| Rustic pavers, shown here in Buff, look like Saltillo tile but will wear better. |

DESIGN TIP: Create the look of Saltillo tile or Mexican pavers with cement tile. It's more durable, requires less care and is available in more sizes, shapes and trim.

|

| Malibu deco tiles on the stair risers with Rustic Pavers in Mission Red for the treads. |

DESIGN TIP: When laying tile on paths that are not square or do not run perpendicular, consider laying them "on point" to avoid mismatched grout lines, or you can use different sizes of tile.

Whether you're recreating the rustic elegance of Old World Spanish bisque or Saltillo tiles, looking for unique formats, or the exquisite beauty of hand-poured plain cement tile, we have a tile that works with your design aesthetic, color palette, and space. Are you looking for Spanish Colonial, Spanish Revival, Moorish-inspired designs, or something slightly more contemporary? No worries. We can help you create a look for a tile walk that is extraordinary, unique and in keeping with a home's architectural style.